In order to ensure that the impact crusher is in a good equipment state and avoid using only maintenance or maintenance, Longjian Group senior editors share with you the correct maintenance and maintenance points of the impact crusher, so as to ensure that the impact crusher can be invested at any time Operation, reduce the downtime of faults, improve the intact rate and utilization rate of impact crusher, reduce the wear of crusher, so as to extend the service life of crusher.

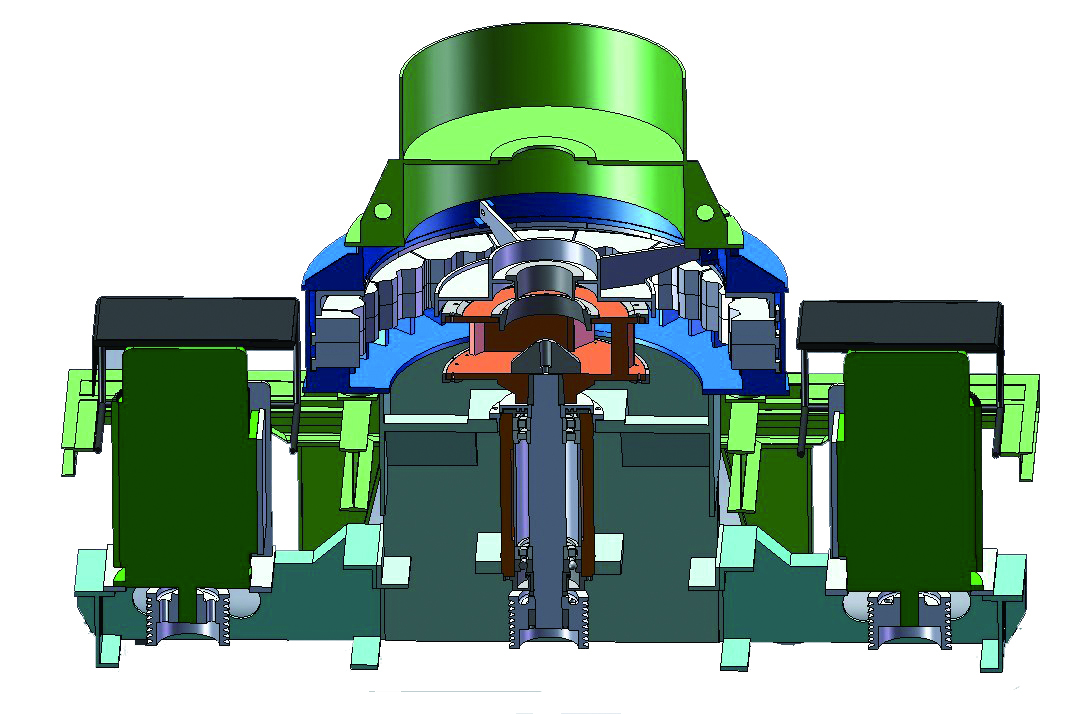

1. Proficient in the working principle of impact crusher

The impact crusher (commonly known as sand making machine), because its working principle is to use the impact force to drop the crushed stone material into the vertical shaft impact crusher feed hopper, enter the high-speed rotating throw wheel through the center feed hole, in It is rapidly accelerated in the spinning wheel, and its acceleration can reach tens of times of gravity acceleration. Then it is thrown out of the spinning wheel at high speed, and then it collides with another part of the material that falls freely after rebound, and then hits the material lining together (stone hitting stone) Or on the counter-attack block (stone-iron), it was rebounded obliquely upward and hit the top of the vortex chamber, and then changed its direction of movement, deflecting downward movement, and collided with the material emitted from the impeller flow channel to form a continuous material curtain. In this way, a piece of material is subjected to two to many chances of impact, friction and grinding in the vortex crushing chamber, and the crushed material is discharged through the lower discharge port.

At the same time, the grain shape of the products produced by the impact crusher is generally in the shape of a cube. It is often used as a high-grade granulated sand making machine in the sand production line, and it is mostly used as a modern building construction material.

Second, how to properly maintain the impact crusher to improve the production efficiency and service life of the equipment?

1. Check equipment strictly. Before production, carefully check whether the installation of the equipment is reasonable and whether any fasteners are loose. It is strictly forbidden to maintain uniform feeding during the production of powdery flammable and explosive materials to prevent overloading or out-feeding of the motor caused by excessive feeding. Blockage of the feed port affects the normal operation of the impact crusher.

2. Strengthen lubrication and maintenance. Before starting the impact crusher, remember to inject lubricating grease, and regularly check the wear degree of each wear-resistant lining ring, lining plate, impeller flow channel lining plate, circumferential guard plate and wear-resistant block. After wear, it should be replaced or repaired in time. After the grinding block is worn, the complete set should be replaced at the same time to ensure the balance of the impeller. Always pay attention to and do a good job of lubricating the friction surface in time to ensure the normal operation of the crusher and extend the service life of the equipment. The bearing is a part of the machine that has a lot of wear and tear. Lubricating grease should be added in time to reduce wear and extend the life of the bearing. Check the bearing status regularly and replace it in time.

3. Adjust the transmission belt regularly. The conveyor belt of the impact crusher should be adjusted regularly to ensure that the transmission belt is evenly stressed.

4. Prevent maintenance during work. When the impact crusher is running at a high speed, the operator should operate in the designated position, and the unrelated personnel should stay away from the equipment. If it needs to be repaired on the machine, it should be performed after the shutdown.

-

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line -

The 2022 Spring Festival holiday notice of Longjian Group

The 2022 Spring Festival holiday notice of Longjian Group -

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021 -

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities -

.png) Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration" -

How to create green mines and green factories?

-

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province -

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association

Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association