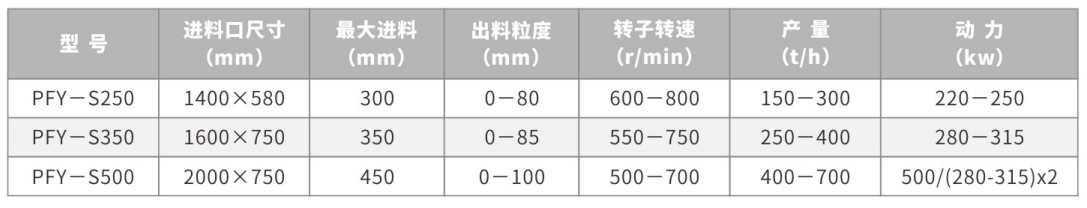

Feeding granularity: ≤450mm

Production capacity: 150-700t / h

Adapt to materials:

Granite, limestone, concrete, quicklime, gypsum, hydrated lime

Application areas:

It is widely used for crushing various soft and medium hard ores. It can be used for coarse crushing, medium crushing and fine crushing in primary crushing and secondary crushing. Mainly used in mining, construction, chemical, cement, metallurgy and other industries.

- Product introduction

- performance feature

- the principle

- TECHNICAL DATA

- project case

This series product is a 2 cavity type counterattack crusher, with large crushing cavity structure, with high yield, crushing ratio, low energy consumption per unit, high utilization rate of wear parts and easy maintenance etc, especially suitable for less than 320 mpa compressive strength of all kinds of material of broken, such as pebbles, basalt, granite, quartz, etc., It is the ideal equipment for high-grade highway, railway, water and electricity, chemical industry, building refractory materials, ceramics, glass and other industries.

1, special super-large cavity design, greatly improve the crushing rate and productivity;

2. Compared with the same type of equipment in the same industry, our company can increase by 10-25% against bankruptcy;

3, the rotor disc vulnerable parts with wear-resistant plate, easy to replace and maintenance;

4, non-circular rotor structure design, give full play to the plate hammer throwing function, greatly improve the crushing efficiency, reduce the wear of the plate hammer, under the same conditions, the service life of the plate hammer is extended about 20%.

5, the use of hydraulic open cover structure, hydraulic adjustment counter frame, maintenance and replacement of accessories is simple and convenient;

6. Simple operation and convenient maintenance.

The impact crusher uses the hammer on the rotor rotating at a high speed to produce high-speed impact on the material fed into the crushing chamber and crush it, and the crushed material is thrown at a high speed along the tangential direction to the impact plate at the other end of the crushing chamber It was broken, and then rebounded from the counterattack board to the hammer, and continued to repeat the above process. During the round trip, the materials also collide with each other. Because the material is hit by the hammer, the impact with the counterattack and the collision between the materials, the material continues to crack, loose and crushed. When the granularity of the material is smaller than the gap between the impact plate and the hammer, it is discharged.

Note: Technical parameters are subject to change without notice.

Note: Technical parameters are subject to change without notice.

-

Sichuan Weiyuan production of 300 tons of fine sand line

Sichuan Weiyuan production of 300 tons of fine sand line -

Chongqing production line of 300 tons of fine washing sand

Chongqing production line of 300 tons of fine washing sand -

Guizhou Daozhenshi 1500t sand aggregate production line

Guizhou Daozhenshi 1500t sand aggregate production line -

.jpg) Sichuan Liangshan sand aggregate production line of 600 tons per time

Sichuan Liangshan sand aggregate production line of 600 tons per time -

At the beginning of the construction of Hubei province, the production line of sand and gravel aggregate was 600 tons

At the beginning of the construction of Hubei province, the production line of sand and gravel aggregate was 600 tons -

.jpg) 400 tons bluestone production line in Myanmar

400 tons bluestone production line in Myanmar

Longjian industrial group reminds you: in order to get in touch with you in time, please be sure to fill in your contact information and demand information, you can enter your requirements, such as the type of raw materials, capacity, feed size, size of the final product, etc.

You can also contact our 24-hour online customer service through online communication software. Longjian industrial group is committed to being your trusted partner.

Our company is a well-known mining machinery manufacturers and stone sand environmental protection equipment complete solution provider, one-stop for you to provide first-class service support and solutions.

National unified sales hotline: 400-023-0808

If you have any questions or concerns, please contact online customer service

Address: Kowloon industrial park, Wanzhou district, Chongqing

- Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

- The 2022 Spring Festival holiday notice of Longjian Group

- Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

- Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

- Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

- How to create green mines and green factories?

- In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

- Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association