SMC pulse bag dust collector is a new type of high-efficiency dust collector improved on the basis of cloth bag dust collector. The improved pulse bag filter retains the advantages of high purification efficiency, large gas processing capacity, stable performance, easy operation, long filter bag life and small maintenance workload.

- Product introduction

- performance feature

- the principle

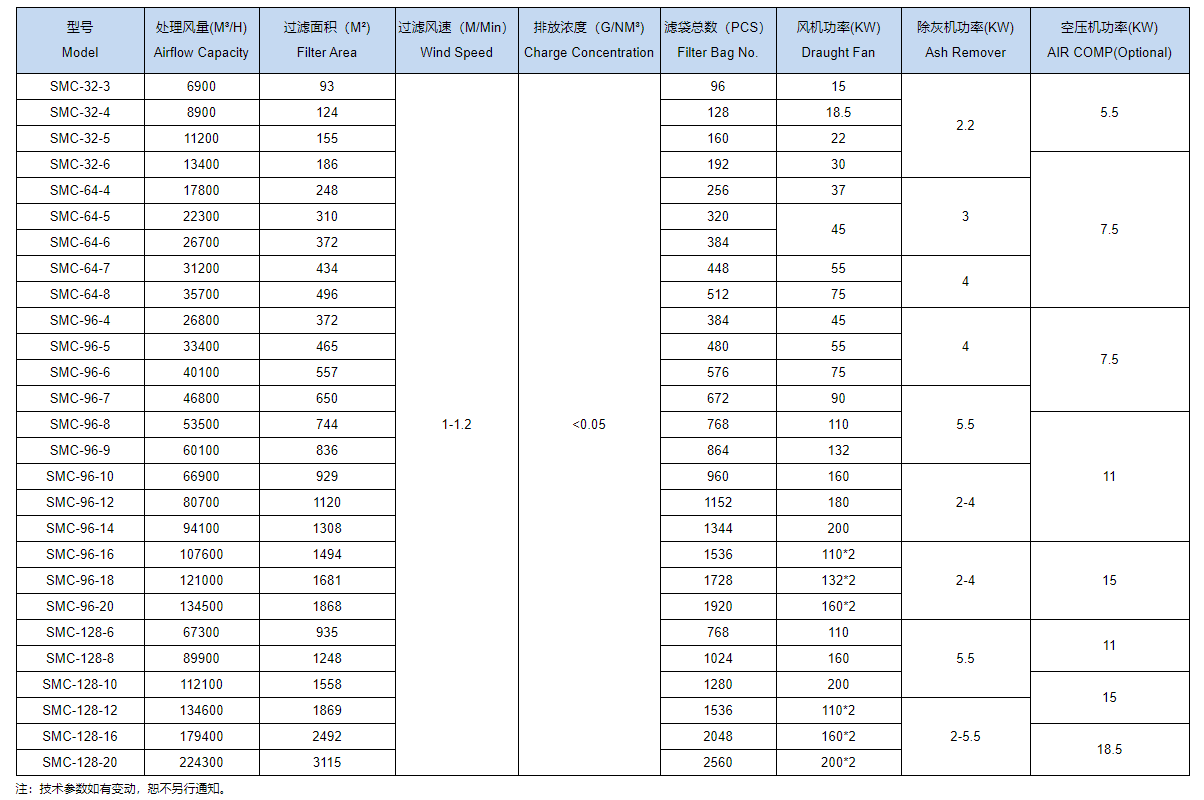

- TECHNICAL DATA

- project case

This product is widely used by the company at home and abroad, and has been continuously improved. It has made great progress in the purification of dust-containing gas. Due to the advanced cleaning technology and the greatly improved gas-to-cloth ratio, it has large processing air volume, small footprint, and purification. High efficiency, reliable work, simple structure, small maintenance, etc. Dust removal efficiency can reach more than 99%. It is a mature, relatively complete and efficient dust removal equipment. When the dust-containing gas passes through the filter cloth, the gap between the fibers of the filter cloth or the gap between the dust adsorbed on the surface of the filter cloth separates the dust larger than the diameter of the gap, which is called screening. For the new filter cloth, due to the large gap between the fibers, this effect is not obvious, and the dust removal efficiency is also low. Only after a certain period of use, a certain thickness of dust layer is established on the surface of the filter bag, the screening effect is more significant. After cleaning, a certain amount of dust remains on the surface and inside of the filter bag, so it can still maintain a good dust removal efficiency. For the needle felt or pile filter cloth, because the felt or pile filter cloth itself constitutes a thick porous filter layer, it can fully play the screening effect, and does not rely entirely on the dust layer to maintain a high dust removal efficiency.

1. Comprehensive use of the advantages of sub-chamber back-blowing and pulse spray cleaning;

2. Overcome the shortcomings of insufficient strength of the sub-chamber backflushing;

3. Solved the characteristics of dust re-adsorption when pulse spray cleaning and filtration are performed simultaneously;

4. Adopt high-energy offline cleaning method, which has the advantages of large cleaning capacity, small system resistance, long filter bag life, high dust removal efficiency, etc.;

When the pulse bag dust collector is working normally, the dust-containing gas enters the ash hopper from the air inlet. Due to the rapid expansion of the gas volume, a part of the coarse dust particles fall into the ash hopper due to inertia or natural settlement, and most of the remaining dust particles As the airflow rises into the bag room, after filtering through the filter bag, the dust particles are retained on the outside of the filter bag. The purified gas enters the upper box from the inside of the filter bag, and then is discharged into the atmosphere through the valve plate hole and the exhaust port. To achieve the purpose of dust removal. As the filtering continues, the resistance of the dust collector also rises. When the resistance reaches a certain value, the cleaning controller sends a cleaning command, first closing the lift valve plate to cut off the filter airflow; then, the cleaning controller pulses The solenoid valve sends a signal. As the pulse valve sends the high-pressure reverse air flow used for cleaning into the bag, the filter bag swells rapidly and generates strong shaking, which causes the dust on the outside of the filter bag to shake off and achieve the purpose of cleaning.

-

Sichuan Weiyuan production of 300 tons of fine sand line

Sichuan Weiyuan production of 300 tons of fine sand line -

Chongqing production line of 300 tons of fine washing sand

Chongqing production line of 300 tons of fine washing sand -

Guizhou Daozhenshi 1500t sand aggregate production line

Guizhou Daozhenshi 1500t sand aggregate production line -

.jpg) Sichuan Liangshan sand aggregate production line of 600 tons per time

Sichuan Liangshan sand aggregate production line of 600 tons per time -

At the beginning of the construction of Hubei province, the production line of sand and gravel aggregate was 600 tons

At the beginning of the construction of Hubei province, the production line of sand and gravel aggregate was 600 tons -

.jpg) 400 tons bluestone production line in Myanmar

400 tons bluestone production line in Myanmar

Longjian industrial group reminds you: in order to get in touch with you in time, please be sure to fill in your contact information and demand information, you can enter your requirements, such as the type of raw materials, capacity, feed size, size of the final product, etc.

You can also contact our 24-hour online customer service through online communication software. Longjian industrial group is committed to being your trusted partner.

Our company is a well-known mining machinery manufacturers and stone sand environmental protection equipment complete solution provider, one-stop for you to provide first-class service support and solutions.

National unified sales hotline: 400-023-0808

If you have any questions or concerns, please contact online customer service

Address: Kowloon industrial park, Wanzhou district, Chongqing

- Focus Project | With a total investment of 487 million yuan, The customer of Sanming Heavy Industry in Liuzhou, Guangxi will soon build an annual output of 4 million tons of fine sand aggregate production line

- The 2022 Spring Festival holiday notice of Longjian Group

- Longjian Group held a virtual equity incentive promotion meeting in the fourth quarter of 2021

- Hand in hand to build heart to heart | Longjian Group Party branch went to Dashu Village to carry out "Urban and rural branches hand in hand" pair to build donation activities

- Chongqing "Meter" high-speed Railway Network Construction | Full Construction in five years, Full operation in ten years -- Chengdu-Chongqing Middle Line high-speed railway Construction "Acceleration"

- How to create green mines and green factories?

- In the process of installation and acceptance of equipment of sand and gravel aggregate production line with production capacity of 600 tons at the beginning of construction in Hubei Province

- Warmly congratulated: Mr. Long Fujian, chairman of the group company, was elected vice president of Chongqing sand and stone association